ACS Wire Harness Restoration Services

Our Wire Harness Restoration Service is a multi-stage process designed to bring your original harness back to OEM-level reliability. Each harness undergoes a full inspection for damage, corrosion, rodent wear, and previous tampering. We strip all insulation to assess internal wire integrity, then submerge the harness in a 48-hour ultrasonic cleaning soak to remove oil, fuel, and contaminants. Damaged wires, terminals, and plugs are repaired or replaced using OEM-grade materials, with each circuit soldered, crimped, and continuity-tested. Before shipping, we perform full pin-to-pin testing and visual quality control to confirm the harness is ready for reliable, long-term performance. Whether you're addressing intermittent ECU faults or restoring a discontinued factory harness, our service provides a cost-effective, long-lasting solution that eliminates guesswork and future electrical issues.

Each Harness undergoes a layered, OEM-quality Restoration p

Visual & Physical Inspection

48‑Hour Ultrasonic Degrease Soak

Visual & Physical Inspection

We meticulously review connectors, routing, insulation condition, rodent signs, wiring integrity, evidence of splices or heat damage.

Complete Strip‑Down Revealed

48‑Hour Ultrasonic Degrease Soak

Visual & Physical Inspection

All electrical tape, boots, and sleeving are removed and exposed allowing us to detect dry, cracked insulation or internal shorts.

48‑Hour Ultrasonic Degrease Soak

48‑Hour Ultrasonic Degrease Soak

48‑Hour Ultrasonic Degrease Soak

Submerged in our proprietary corrosion inhibiting solution, the harness is thoroughly cleaned of oil, fuel, grime, and contamination.

OEM‑Grade Repair & Replacement

High‑Temp Rewrapping & Sleeving

48‑Hour Ultrasonic Degrease Soak

Anything compromised—wires, pins, terminals—are replaced. Repairs are crimped, soldered, heat-shrinked, and fully continuity-tested. End to End if needed ONLY!

High‑Temp Rewrapping & Sleeving

High‑Temp Rewrapping & Sleeving

High‑Temp Rewrapping & Sleeving

We rewrap using automotive-grade insulation and protective loom designed to withstand vibration, abrasions, high heat, and environmental stress.

Final Continuity and QC Testing

High‑Temp Rewrapping & Sleeving

High‑Temp Rewrapping & Sleeving

The restored harness is tested pin‑to‑pin, visually inspected, and checked for proper functioning prior to shipping.

To Start your Restoration click below!

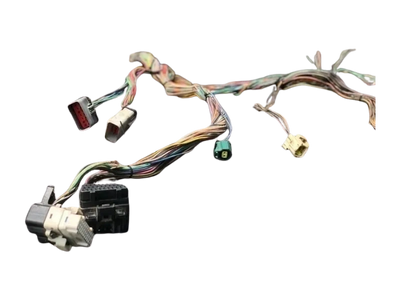

Harness Gallery

Copyright © 2017 Auto Computer Specialist - All Rights Reserved.

ACS Is Privately Owned & Operated ACS is not Affiliated with any Company

ACS reserve all rights to refuse service to anyone.